- 1Parthenope University of Naples, Italy

- 2INAF, Roma, Italy

- 3INAF - IAPS Rome, Rome, Italy

Introduction:

The COMET INTERCEPTOR mission will perform an encounter with a Dynamically New Comet (DNC) and with its three spacecraft (S/C A, S/C B1 and S/C B2) will study different aspects of the comet (tail, nucleus, and atmosphere) with a multi-point approach. DISC (Dust Impact Sensor and Counter) is an instrument, on board the spacecraft A and B2 of COMET INTERCEPTOR, devoted to the analysis of comet dust particles mass properties. Here is presented an analysis of the instrument measurement performances, applying numerical simulations with ANSYSTM and AUTODYNTM platforms, to simulate sensing element mechanical behaviour. The particle impacts against the instrument sensing element are identified as HVI (Hypervelocity Impact). The dedicated modelling approach is based on a simulation chain based on the three-dimensional smooth-particle hydrodynamics (SPH) and Finite Element (FE). This chain was developed to gain an insight into characteristics of HVI-induced AE (Acoustic Emission) propagation inside the instrument.

Instrument working principle

DISC (Fig 1) consists of a single aluminium box containing the electronics and the sensing plate located on the top side of the box. The sensitive element consists of 3 zirconate piezoelectric sensors (PZT), glued at the corners of a 0.5 mm thick aluminium plate forming a 100 x 100 mm2 sensitive area. DISC aims to determine: dust mass distribution; dust particle count; dust impact duration; dust density/structure; dust coma structures.

Figure 1: DISC

Modelling Shock Waves Under HVI- Principles:

Combining particle-based SPH and element-based FE is a balanced model configuration to guarantee both calculation efficiency and accuracy. SPH can well characterize the large material distortion and compression induced by HVI. Nevertheless, discretizing the entire model with SPH will lead to an enormous effort spent on calculation. Hence, SPH is only applied to the region with large material distortion and compression (near the impact), and FE is introduced for the discretization of the region with a linear elastic response.

In SPH, the investigated structure is discretized into particles and there is no fixed connection between any two particles. The integral representation of a function (e.g., displacement) at particle i is approximated, in terms of its neighbouring particles in a support domain Ω. At each step of calculation, updated neighbouring particles for particle i are searched first (because material undergoes extreme deformation during HVI and Ω may involve different numbers of particles at each step) and then the computation is carried out based on the updated Ω.

Because HVI makes part of the target structure behave like a fluid and go through high compression, modelling of wave propagation in the target structure lies on the Navier–Stokes (NS) equation in this approach.

Equation of state (EOS), strength model, and failure criterion were introduced to the modelling as a supplement to NS equations.

Simulations Chains:

Starting from the theory explained, the analysis of instrument capability was conducted, by involving the ANSYSTM and AUTODYNTM platforms.

To obtain accurate results, but within a reasonable computational time, the effect of a particle impact on the sensing element of DISC test is simulated through a sub-simulations system, shown below:

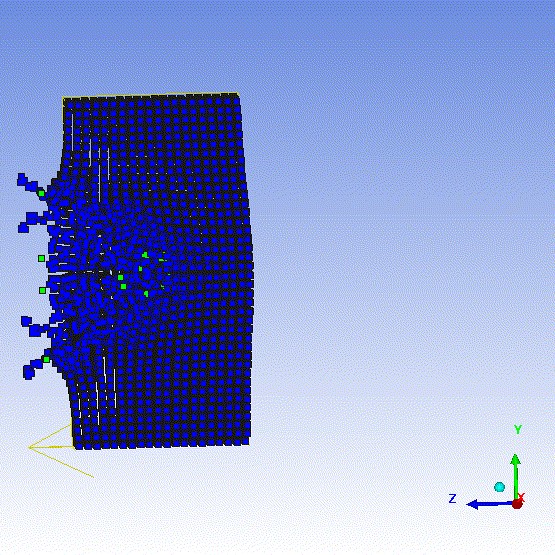

1. Explicit dynamics analysis + Autodyn Tool (integration time 0 -> 1E-6 s): simulation involving the SPH part, settled before (Fig 2), and a FE discretize “stripe” (Fig 3) of the plate, aimed at saving the behaviour at the boundaries between SPH particles and FE elements, in terms of stress, deformation and velocity (Fig 4);

Figure 2: SPH plate after the HVI in the pre-simulation aimed at the model set. The SPH part is dimensioned such that the material behaviour at the surrounding FE area is elastic.

Figure 3: SPH discretized part + FE surrounding stripe.

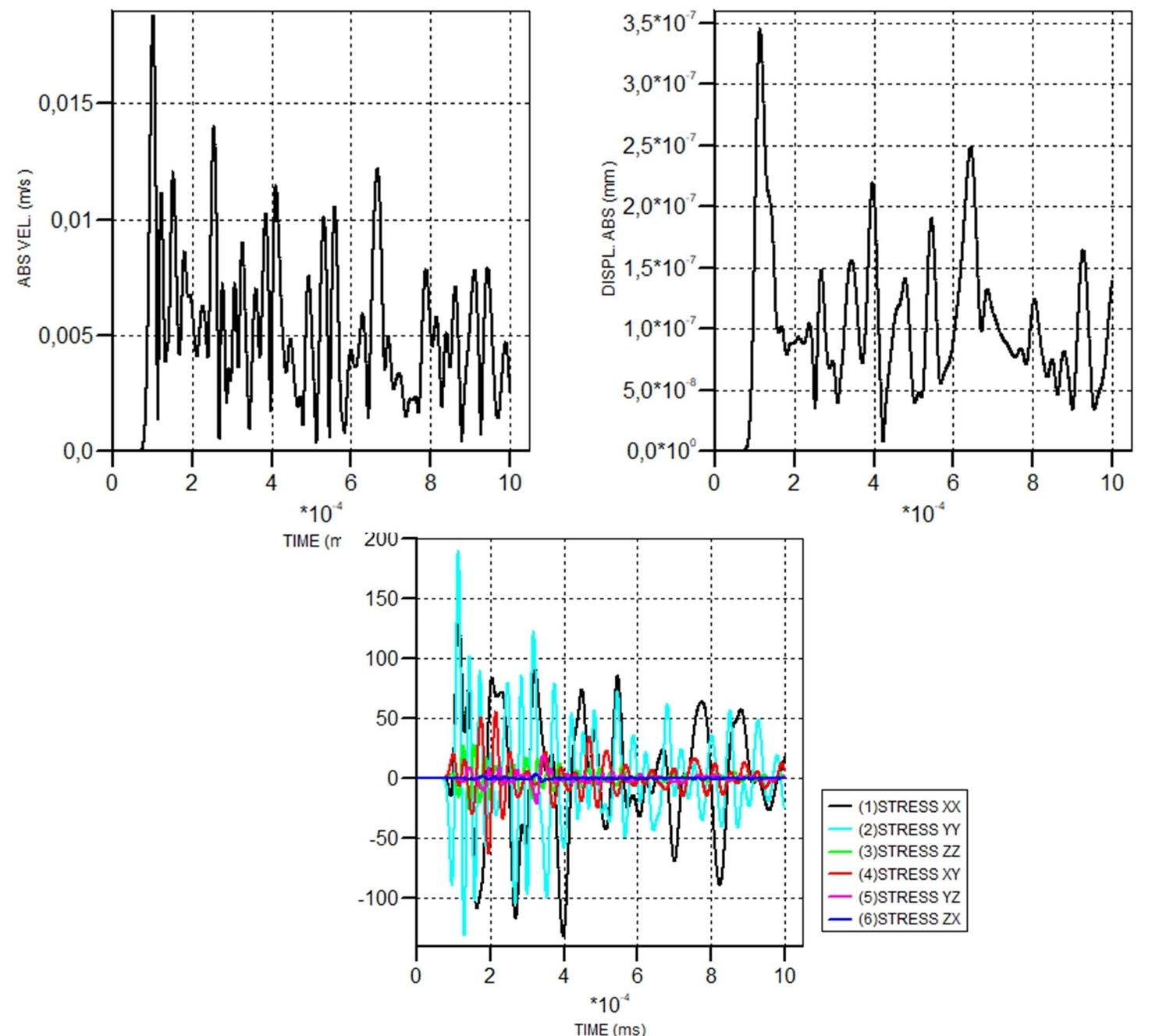

Figure 4: Velocity (upper left), Deformation (upper right) and Stresses (lower) graphs relative to a node at the boundary between SPH and FE part.

2.Transient structural analysis (integration time 0 -> 1E-6 s): the output of the previous analysis is used as input in this simulation, which includes, differently from the previous, the entire sensible plate. In this phase it is possible to obtain the effects of the HVI impacts at the plate edges;

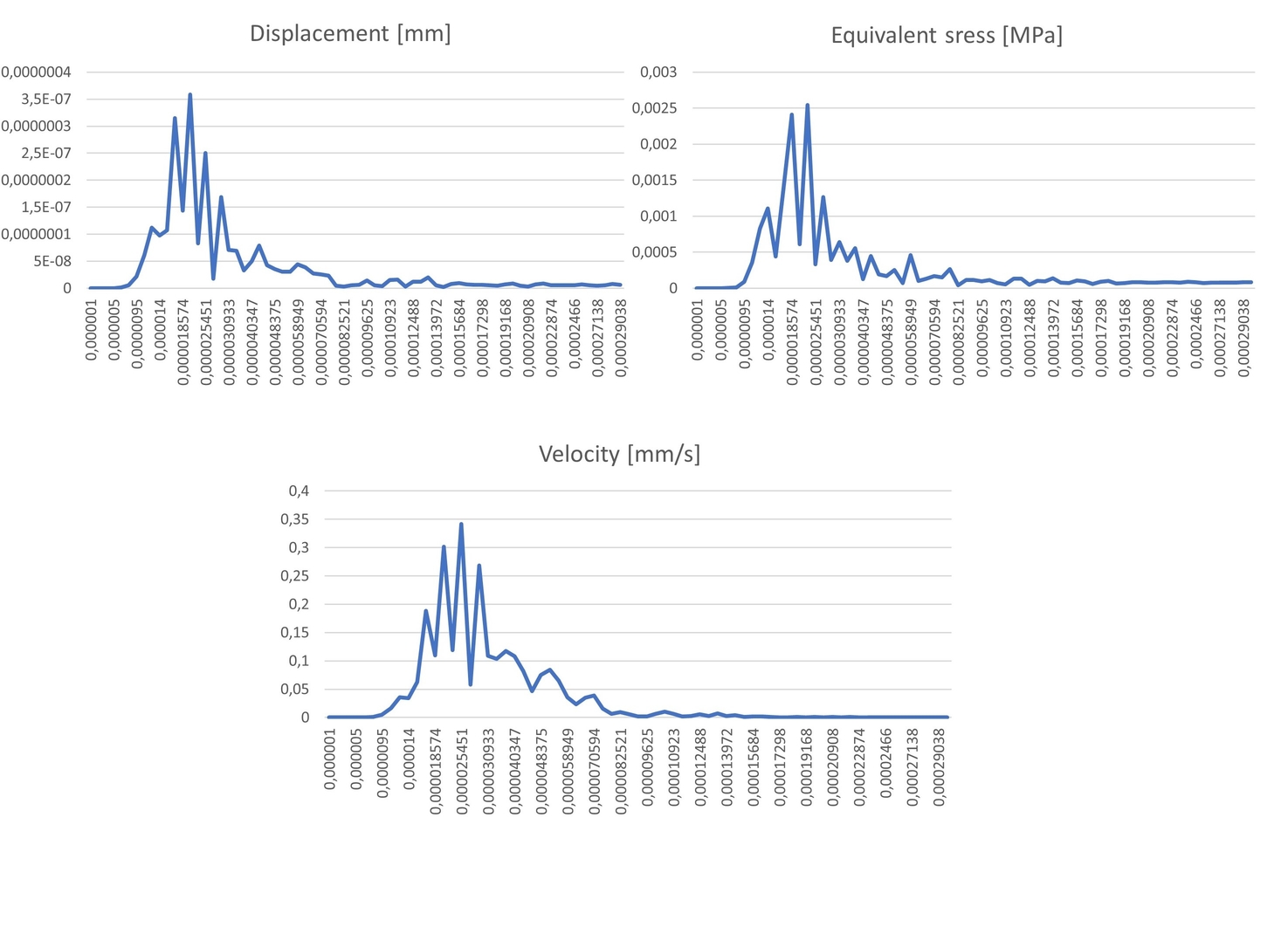

3.Transient structural analysis (integration time 1E-6 -> 3e.4 s): again, the output of the previous analysis is used as input in this simulation, aimed at following the mechanical behaviour of the sensing element during the measurement (Fig 5);

Figure 5: Displacement (upper left), Stress (upper right) and Velocity (lower) relative to a node in correspondence of a PZT.

4. Transient Structural analysis + PZT Module (integration time 0 -> 3e.4 s): same simulation setting of the previous one, plus four PZT sensors positioned at the edges of the sensible plate aimed at computing the voltage.

In this work preliminary results, showing the full simulation of the DISC sensing part (from impacting particle to PZT signal), are presented.

Acknowledgements: This research was also supported by the Italian Space Agency (ASI) within the "Partecipazione italiana alla fase 0 della missione ESA Comet Interceptor " (ASI-INAF agreement n.Accordo Attuativo" numero 2020-4-HH.0 ).

How to cite: Piccirillo, A. M., Della Corte, V., Rotundi, A., Inno, L., Longobardo, A., Di Paolo, F., Ferraioli, G., and Zakharov, V.: DISC-Modelling and Simulation chain of Hypervelocity Impacts, Europlanet Science Congress 2021, online, 13–24 Sep 2021, EPSC2021-618, https://doi.org/10.5194/epsc2021-618, 2021.