- 1Universität Münster, Institut für Planetologie, Münster, Germany (bastian.gundlach@uni-muenster.de)

- 2Institute of Space Systems (DLR), Robert-Hooke-Straße 7, 28359 Bremen, Germany

- 3Max Planck Institute for Solar System Research, Justus-von-Liebig-Weg 3, 37077 Göttingen, Germany

Introduction: Recent missions, Hayabusa2 and OSIRIS-REx, successfully brought back significant samples from the near-Earth asteroids Ryugu and Bennu [1, 2]. Hayabusa and its successor employed a method of collecting surface grains through impact mobilization. In contrast, OSIRIS-REx used pressurized nitrogen gas to push material into its collection device. Although Touch-And-Go (TAG) manoeuvres are commonly used for asteroid sampling, recent lunar missions, such as the Luna and Chang'e programs [3, 4], have adopted more controlled techniques involving landers that drill and scoop material. During the Apollo program, astronauts primarily collected samples manually using various tools. For the MarcoPolo-R mission study [5], an alternative sampling method, the Brush Wheel System (BWS), was developed and tested, though ultimately not implemented. This system aimed to brush material into a container during landing [6]. To explore and refine another sampling mechanism suitable for both TAG and landing manoeuvres, previous work [6-8] has been examined. This mechanism will be adapted and optimized for a mission profile different from MarcoPolo-R, with the goal of effectively sampling a broad spectrum of grain sizes, applicable to both lunar and asteroidal environments.

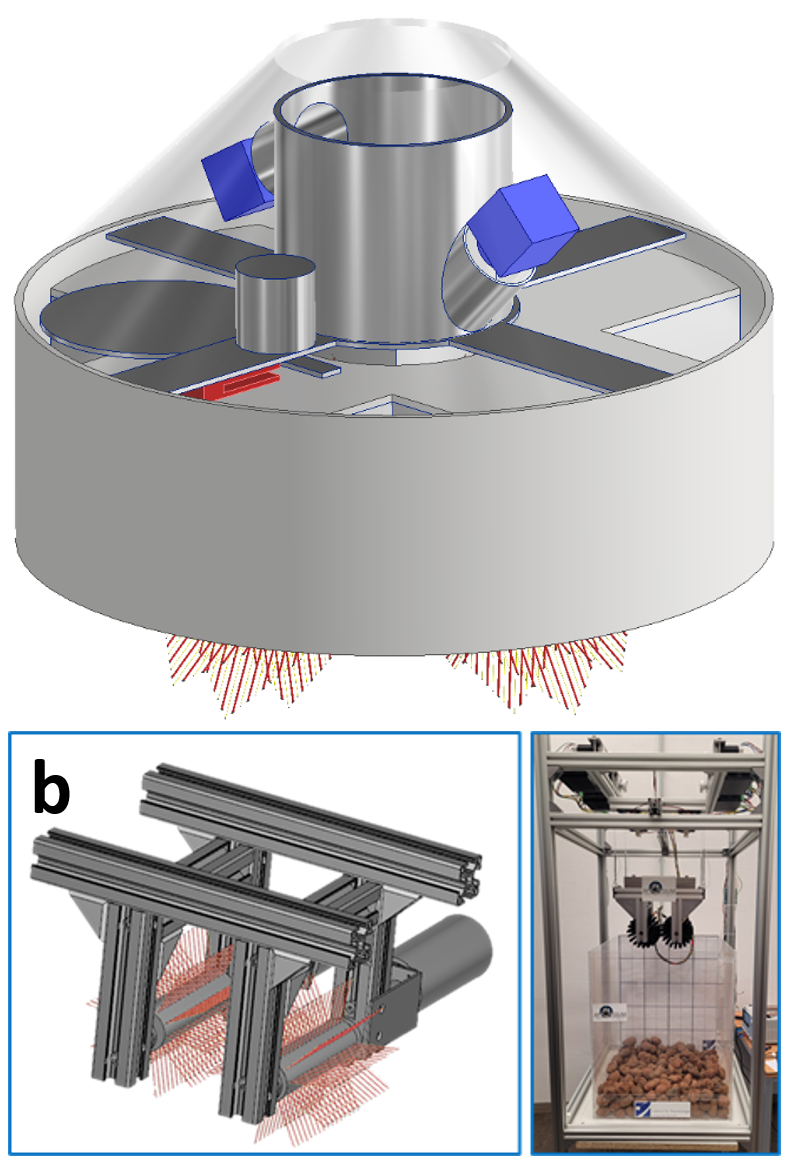

Sampler Design: The APOphiS SUrface saMpler (APOSSUM) concept has undergone investigation and development in two concurrent engineering studies at DLR Bremen in 2024, in collaboration with DLR and MPS Göttingen [9, 10]. The initial mission design targeted Apophis' flyby in 2029, when it will pass Earth at a distance of less than 32,000 km. The Brush Wheel System (BWS) was developed as the primary instrument for acquiring grains up to 5 cm in diameter during a TAG maneuver. Currently, the APOSSUM (renamed to Asteroid PrObe Sampler and Sample retUrn Mission) system shall be implemented as a payload for the PRIAMOS mission proposal to sample regolith from a D-type asteroid and for the CoSi mission proposal to study the uppermost surface of a comet. The design of the Brush Wheel System (BWS) features two cylindrical brushes, each 100 mm in length and 100 mm in diameter, driven independently by brushless DC motors. Surface particles ranging from sub-millimeter to centimeter sizes are captured, lifted, and moved into the sampling tube for subsequent collection. A test setup was created to simulate a Touch-And-Go (TAG) maneuver within a 45 cm square sample box. To achieve this, the sampler is suspended by four Dyneema strings, enabling a controlled descent at speeds up to 20 cm/s and at varying angles relative to gravity and/or the sample surface. The flight instrument design incorporates two cameras, providing views of both the surface interaction area and inside the sampling tube. Unlike the breadboard, the flight design may adopt a four-brush configuration, which will be evaluated against the two-brush design based on sampling efficiency, system redundancy, and overall complexity.

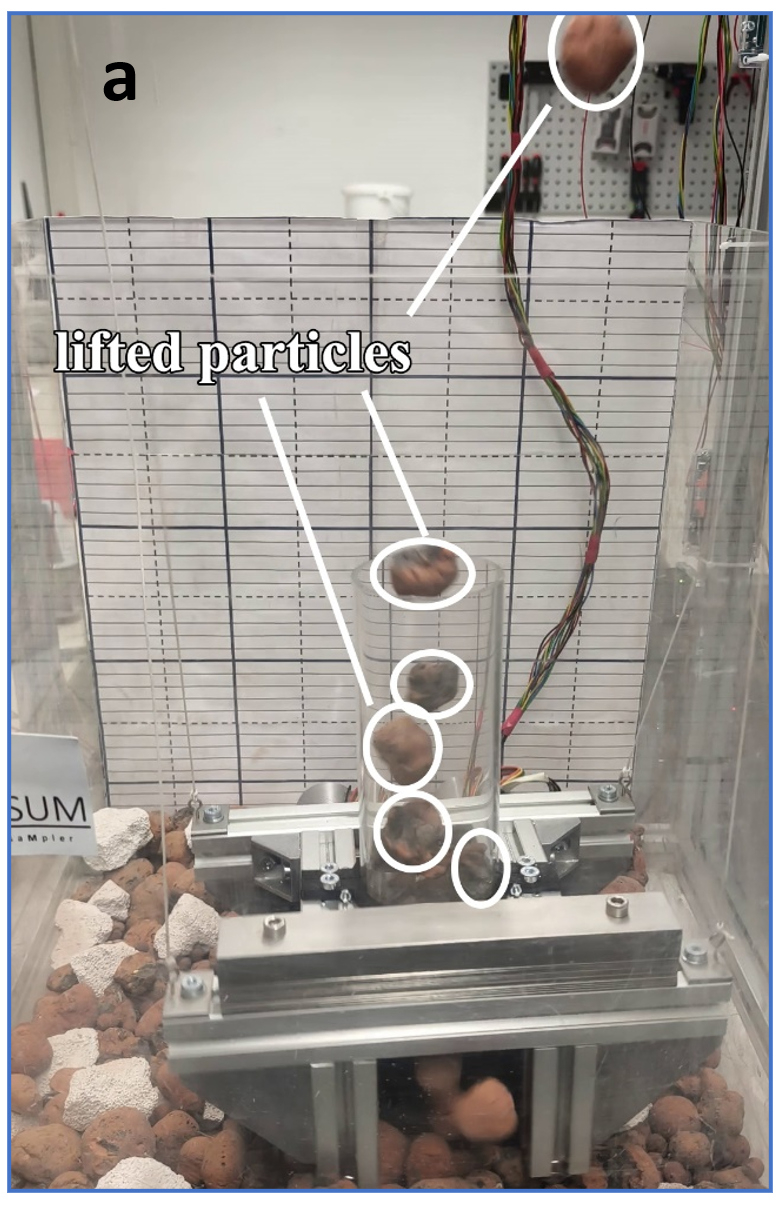

First Test Results: The breadboard design underwent extensive testing across a broad spectrum of parameters within our dedicated facility. Particle size and the BWS motor speed emerged as crucial factors influencing sampling efficiency. Notably, particles up to 5 cm in diameter could be sampled with satisfactory efficiency even under Earth's gravity. Currently, porous clay (LECA) and fractured Ytong rocks serve as analogue materials, which can be optionally combined with sand to simulate finer regolith. The use of lunar and Martian soil simulants is also feasible and planned to validate the concept with specific grain size distributions. Motor speeds in the range of 300 to 400 rpm struck a favorable balance between sampling efficiency and motor power requirements, a finding corroborated by our tests. Brush blockage occurred more frequently at lower rotation speeds (e.g., 200 rpm) and at 400 rpm, particles around 40 mm in size were ejected several decimeters from the surface. Other tested parameters included the relative surface angle, particle shapes and sizes, and contact force. Overall, the concept demonstrated robustness against these variations, although sampling efficiency was affected. In the event that a particle larger than the gap between the brushes causes them to jam, a reverse rotation can clear the obstruction, allowing for a subsequent sampling attempt.

Upcoming Development: The Brush Wheel System (BWS) is currently undergoing modifications to ensure compatibility with vacuum environments including brushless DC motors. It will be tested in zero-gravity and simulated lunar gravity conditions during two campaigns in June and October at the Drop-Tower and GraviTower facilities at ZARM in Bremen. Key objectives of these campaigns are to: 1) investigate the interaction between the brushes and the surface material, and 2) validate the system's efficiency under zero- and low-gravity for a range of system parameters. These parameters are consistent with those tested in the atmospheric setup described in the preceding section. Additionally, breadboard model incorporating four brushes is tested under Earth's gravity. Initial test results from the zero-gravity and simulated lunar gravity campaigns will be presented at the conference.

Acknowledgement: We acknowledge financial support by the DLR Agency (50OO2511).

Fig. 1: a) CAD model of the BWS flight design consisting of 4 diamond-shaped brushes, a flap to close the sampling tube and two cameras (blue) to observe surface interaction and material inside the sampling tube. b) BWS breadboard with two cylindrical brushes. c) Test facility to simulate TAG maneuver under Earth gravity.

Fig. 2: Snapshot from a video during a test with a brush rotation speed of 400 rpm and an approach velocity of 20 cm/s on ~30-40 mm LECA clay and Ytong rocks. After surface contact many particles are lifted and partially flying up to a meter high (arrow) reaching velocity of ~1 m/s.

References:

[1] Watanabe S. I., et al. (2017) Space Science Reviews, 208, 3-16.

[2] Lauretta D. S. et al. (2024) Meteorit. Planet. Sci., 59, 2453-2486.

[3] Florensky et al (1977) Proc. 8th Lunar Sci. Conf., 3257-3279.

[4] Xiao et al. (2021), Sample return missions, 195-206.

[5] Barucci M. A. et al. (2012) Exp. Astron., 33, 645–684.

[6] Bonitz R. (2012) IEEE Aerospace Conference, Big Sky, MT, USA, pp. 1-6.

[7] Zhang J. et al. (2022) Acta Astronautica, 198, 329-346.

[8] Luo H. et al. (2023) Front. Mech. Eng., 18, 16.

[9] Grundmann J. T. et al. (2025) Apophis T-4 Workshop.

[10] Goldmann M. et al. (2025) Apophis T-4 Workshop.

How to cite: Gundlach, B., Patzek, M., Goldmann, M., Güttler, C., Klingenberg, G., Aussel, B., Grundmann, J. T., and Hilchenbach, M.: APOSSUM – A Brush Wheel System Sampler for Asteroidal Regolith , EPSC-DPS Joint Meeting 2025, Helsinki, Finland, 7–12 Sep 2025, EPSC-DPS2025-1251, https://doi.org/10.5194/epsc-dps2025-1251, 2025.