Influence of thermal fatigue on the microstructure of Mercury’s surface

- 1Luleå University of Technology, Kiruna, Sweden (erika.kaufmann@ltu.se)

- 2ESA/ESTEC, Noordwijk, The Netherlands

- 3ESA/ESAC, Villanueva de la Canada, Madrid, Spain

Thermal fatigue is one of the processes governing regolith generation on asteroids and planetary surfaces. Although meteorites have been extensively studied to date, information on surface changes triggered by thermal cycling on slow rotators is limited. Thermal fatigue occurs because (a) of the mechanical stresses caused by the differential expansion, itself caused by different degrees of heating and (b) different thermal expansion coefficients of the mineral grains within a rock. The underlying assumption for the effectiveness of thermal fatigue is that the number of thermal cycles increases the total action, i.e. the effectiveness of fracturing by thermal cycling does not wane over many cycles. This would make thermal fatigue an effective regolith production mechanism on (fast-rotating) asteroids but less effective on a slow rotator such as Mercury. However, this assumption contradicts a lesser-known phenomenon in mechanical engineering, the so-called Kaiser effect (Holocomb, 1993). This is the observation that the progress of mechanical fatigue under a cyclical mechanical load can only progress significantly if the amplitude of the mechanical load cycle is increased. In other words: thermal cycling with the same thermal (and thereby mechanical) amplitude will not result in continuous crack propagation, making repeated thermal fatigue less effective. High amplitude cycles and low frequency thermal cycles, on the other hand, could in these circumstances play a much more important role.

To get more insight into thermal fatigue on Mercury, a study was conducted at Luleå University of Technology by exposing rock samples to several heating/cooling cycles comparable with those that rocks experience on the surface of Mercury.

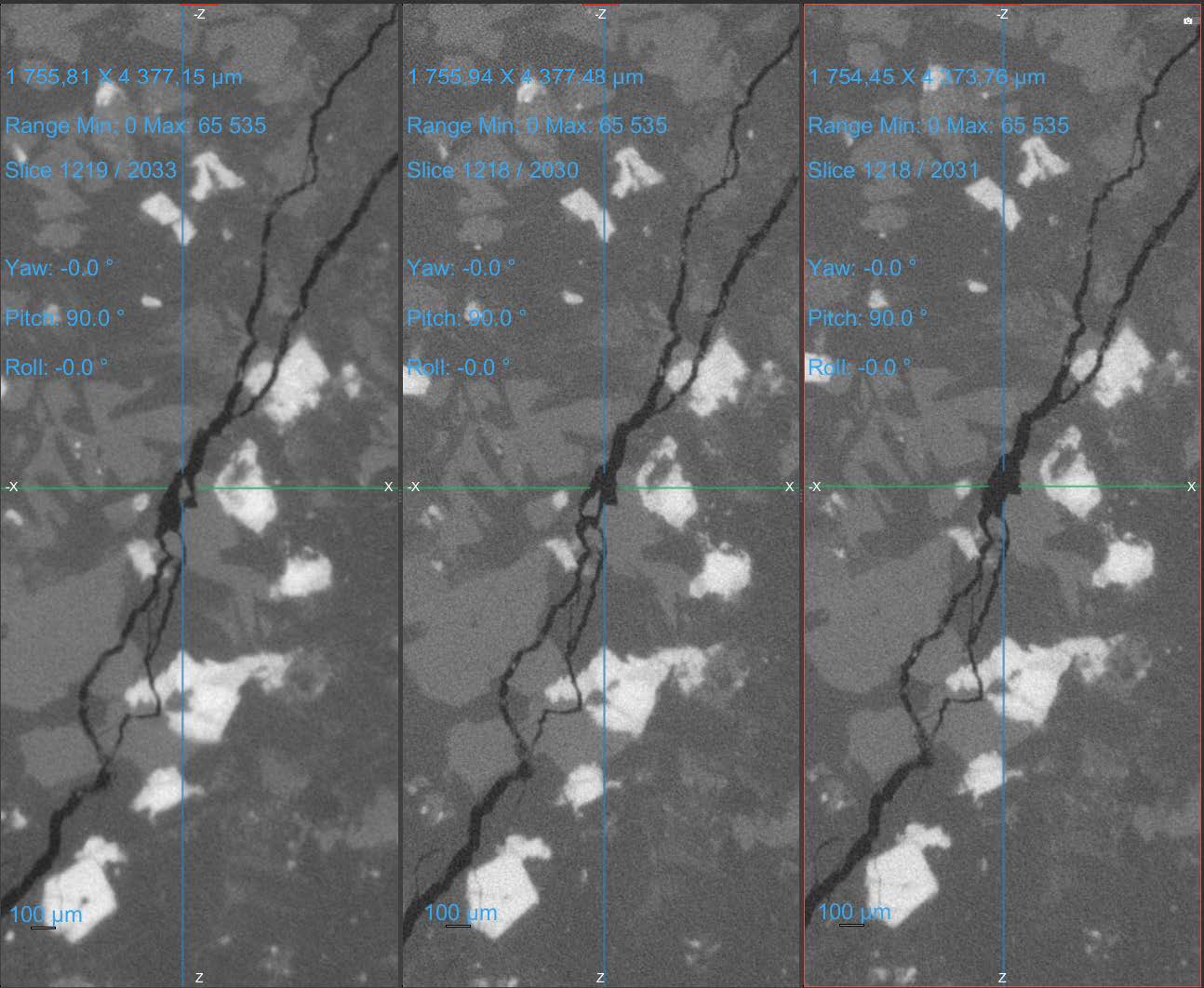

For this purpose, cylindrical samples of various types of rocks were periodically heated and cooled. In order to ascertain whether cracks are evolving due to thermal cycling, X-ray Micro Computer Tomography (XCT) scans were performed before and after the first temperature cycle as well as after the final cycle.First analysis showed that no changes or newly formed cracks could be observed in samples that have a low porosity and/or low mineral diversity. It also could be seen that distinct changes inside the samples could only be observed in a large pre-existing crack in an Andesite sample as shown in Figure 1. Further it was noticed that all samples exhibited a variation in surface color after the first heating cycle. This might be caused by chemical weathering related to oxidization or (de)hydration, although further analysis is necessary to confirm this.

Figure 1: Comparison of images taken of a specific spot before the first temperature cycle (left), after the first temperature cycle (middle) and after the final temperature cycle (right).

References:

Holocomb, D.J., 1993. General Theory of the Kaiser Effect, International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, Vol 30, No 7, doi.org/10.1016/0148-9062(93)90047

How to cite: Kaufmann, E., Hagermann, A., Lycksam, H., Forsberg, F., Latsia, N., Benkhoff, J., Besse, S., and Zender, J.: Influence of thermal fatigue on the microstructure of Mercury’s surface, Europlanet Science Congress 2024, Berlin, Germany, 8–13 Sep 2024, EPSC2024-57, https://doi.org/10.5194/epsc2024-57, 2024.