In-situ extraction and purification of water on the moon – the LUWEX project

- TU Braunschweig, Institut für Geophysik und Extraterrestrische Physik, CoPhyLab, Germany

For the future of sustainable space exploration, In-Situ Resource Utilization (ISRU) plays a key role. Thus, the investigation and development of new technologies focusing on utilizing local resources is crucial to cost-effective robotic and human space missions with less logistical effort. Water does not only serve as consumable for astronauts and plants but also as rocket propellant by electrolysing it into hydrogen and oxygen.

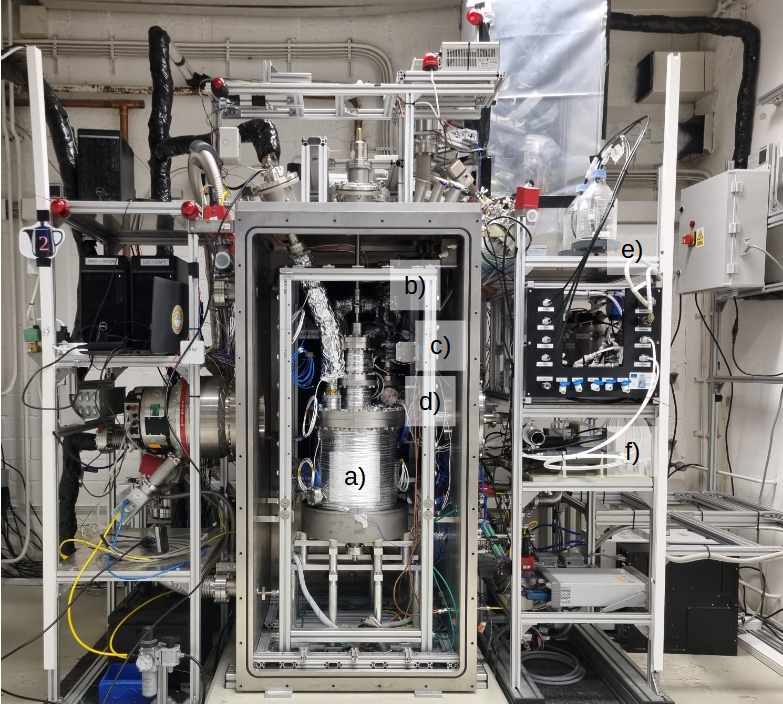

Therefore, the LUWEX (Validation of Lunar Water Extraction and Purification Technologies for In-Situ Propellant and Consumables Production) project aims to develop and validate a technology demonstrator for the extraction of water from icy-lunar-regolith simulant, the following purification and quality monitoring. Several experiments with different mixing ratios and material compositions will be conducted. The Technology Readiness Level (TRL) is increased for the whole process chain from TRL 2 and 3 to TRL 4 based on the planned experiments. The extraction, capturing and liquefaction subsystems are placed inside the thermal-vacuum chamber (TVAC) of the Comet Physics Laboratory (CoPhyLab) at TU Braunschweig, detailed in Kreuzig et al. 2021, to simulate the relevant lunar environment. The TVAC, including the extraction, capturing and liquefaction subsystems inside it, is shown in Fig.1. This image also shows the purification and quality monitoring subsystems placed on the tray on the right side of the chamber. Two liquid nitrogen cooling systems are utilized to cool the TVAC to an ambient temperature of around 100 K. The working pressure inside the TVAC is around 10-5 mbar. To realize the control of all subsystems inside the TVAC, a complex valve system, including 20 electric-pneumatic valves, is installed around it. Further, an electric-pneumatic slider is mounted between the capturing and liquefaction subsystems inside the TVAC (see Fig.1c). This is necessary as a cold trap consisting of two 3D-printed, actively cooled copper-cones is utilized to capture water vapour extracted from the regolith by heating with the liquefaction chamber mounted below it. Once water ice has deposited onto the cold trap, it is heated to release the ice into the liquefaction chamber. There, the ice is liquefied by heating the liquefaction chamber. To liquefy the ice, the pressure inside the liquefaction subsystem needs to increase to the vapour saturation pressure of water. The chamber is, therefore, separated from the cold trap utilizing the above-mentioned slider.

Besides providing an artificial lunar environment, the CoPhyLab is responsible for the production of icy simulant. Therefore, granular water ice with a mean grain size of 2.4 microns, which is produced with the ice machine outlined in Kreuzig et al. 2021, is mixed with lunar Highland simulant by Lunex Technologies. To prevent any thermal evolution of the water ice, the mixing is performed by adding liquid nitrogen to the materials. In the resulting mixture, the water ice particles are expected to be evenly distributed in the regolith. During the water ice production, impurities such as CO2 or methanol can be added.

The experiments with the LUWEX system will be performed in Summer 2024, and the first results will be presented in September. Firstly, an experiment run with an icy-lunar-regolith sample with around 50% water ice in mass is planned to characterize and test the sample preparation, infilling and the extraction, capturing and liquefaction subsystems. Then, icy-regolith samples with 5%, 10% and 15% water ice in mass will be realised, and the complete process chain, including purification and water quality monitoring, will be tested.

More information on the LUWEX project is available at https://luwex.space.

Figure 1: The CoPhyLab TVAC with the extraction (a), capturing (b) and liquefaction (d) subsystems mounted inside. A slider is installed between the capturing subsystem and the liquefaction (c). On the right side of the TVAC, the purification subsystem is placed with two storage tanks (e). Below the purification sits the quality monitoring subsystem (f). Image credit: Luca Kiewiet

References:

Kreuzig, C. et al. (2021). “The CoPhyLab comet-simulation chamber”. Review of Scientific Instruments 92.11, S.115102.

How to cite: Brecher, N., Kreuzig, C., Meier, G., Schuckart, C., and Blum, J.: In-situ extraction and purification of water on the moon – the LUWEX project, Europlanet Science Congress 2024, Berlin, Germany, 8–13 Sep 2024, EPSC2024-87, https://doi.org/10.5194/epsc2024-87, 2024.